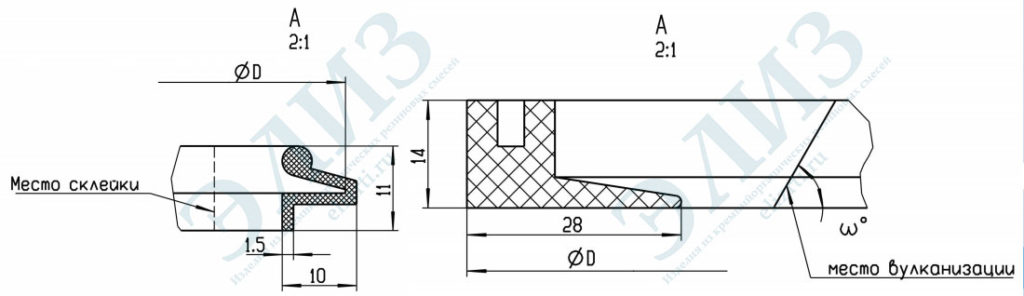

A special adhesive is used for gluing silicone products in a closed loop. It is applied to a section of a dry, non-greasy surface. If it is necessary to improve the adhesive characteristics, use

an adhesion primer.

The surfaces to be bonded are docked together and held in this position until they reach the desired height.

required functional strength. The adhesive cures with air moisture at room temperature.

The time of formation of the surface film is 10-90 minutes, complete drying of the adhesive occurs in 12-72 hours

(depending on the brand).

End-to-end vulcanization is performed in a mold heated to the required temperature. Rubber compound is applied

on a cut of a dry, non-greasy surface. The ends of the profile are joined together

and are kept in the mold until the rubber mixture is completely vulcanized (10-30 minutes).

In each individual case, preliminary tests are recommended to assess the adhesive strength.